Remember the pandemic we’d rather forget? Desperate for everyday items like toilet paper, consumers who’d given little thought to the supply chain suddenly discovered why it matters.

In publishing, those who’d taken the supply chain for granted found their businesses upended by shortages of paper, glue, and labor.

But that’s all over now, right?

Not exactly. While some parts of the supply chain have recovered post-pandemic, publishers are still contending with weak or broken links that affect their bottom line. Yet with characteristic resilience and ingenuity, independent publishers are discovering workarounds and improving practices to counter supply chain challenges.

Production Woes

At Ulysses Press, CEO Keith Riegert cites printing and shipping as the biggest issues for his company. “There is nothing worse than seeing a 5,000-unit retailer order disappear because you missed your pub date by two weeks,” he says.

For the cause of such woes, Riegert points to mass consolidation in the print business and freight operations that have yet to stabilize post-pandemic. “That means fewer options and less reliability, which is resulting in higher cost of goods sold and nerve-wracking shipping timelines,” he says. “On the shipping side, it seems to be a rolling disaster, from port and customs delays that have pushed back on sale dates to issues with the Red Sea jacking up prices from Asia.”

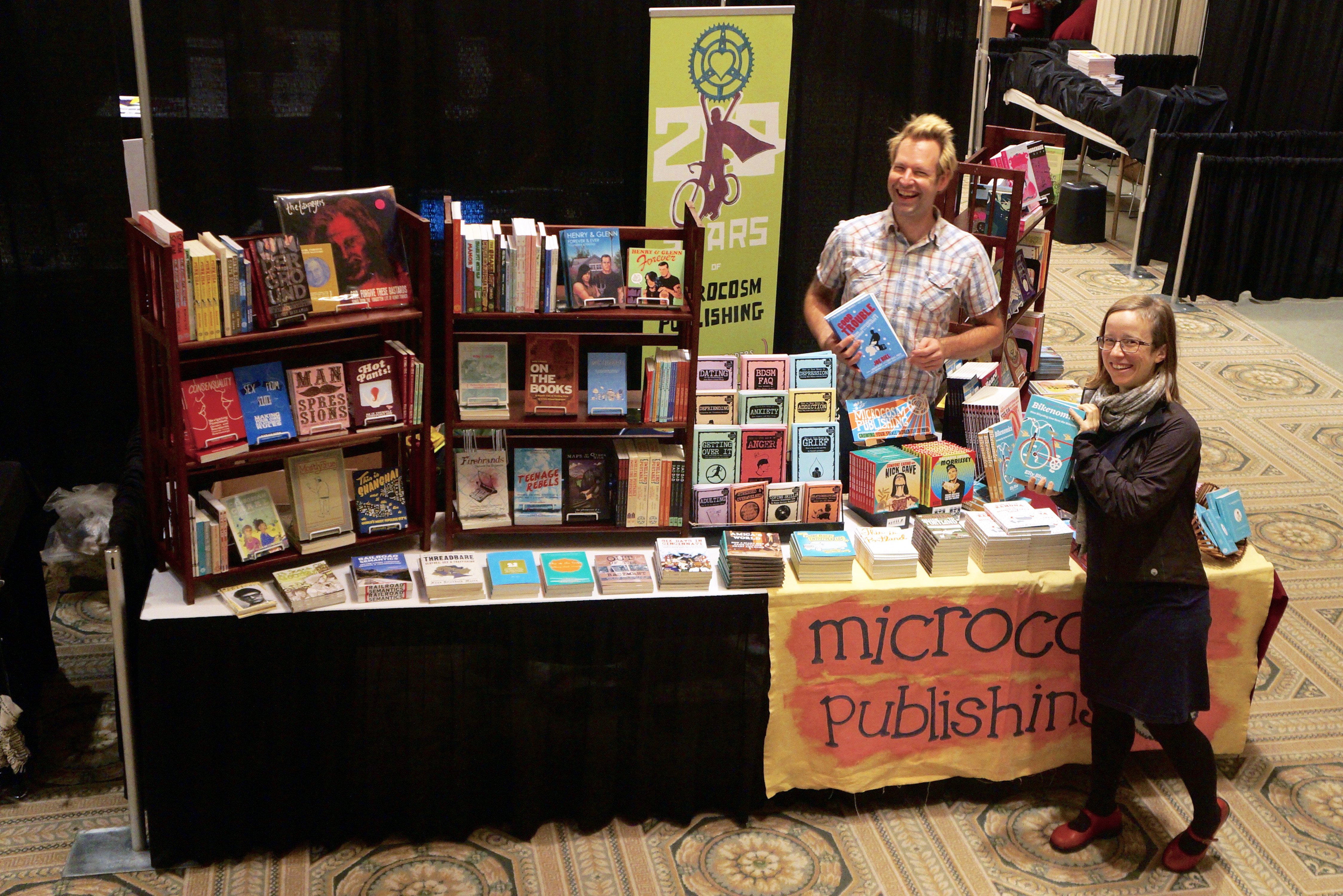

Joe Biel, founder and CEO of Microcosm Publishing, notes the supply chain challenge of elevated printing costs. “In October 2022, we published four big books, big in terms of print run—10,000 each—and in terms of production values and cost. This was, seemingly, the peak of paper costs.”

With the added expense, Biel’s profit-and-loss numbers went out the window, with production on some titles running double from what he’d planned on. He worried that if the trend continued, costs would double and sales would collapse.

Fortunately, things never got that bad. Biel estimates that, overall, printing costs only went up 15% on net for the year. “We compensated by increasing cover prices accordingly, and this seemed fine with retailers,” he says. In the long run, he thinks the industry may even benefit from the price hikes since higher cover prices mean increased revenues for stores.

At Wolfram Media, managing editor Paige Vigliarolo says that while the supply chain is working better than at the height of the pandemic, persisting problems have forced workarounds. When Wolfram’s printer got backed up and had trouble getting paper, the company had to move release dates. To mitigate that issue, Wolfram has shifted from offset runs to print on demand (POD) for some projects. “We were pleasantly surprised with the quality,” she says.

Stone Bridge Press publisher Peter Goodman reports hitting release dates but says he has had trouble getting reprints in a timely manner due to paper shortages and long lead times at printers. For POD titles through Ingram’s Lightning Source (LSI), he also reports having to deal with spine, cover alignment, and interior text issues.

Working on what she describes as “mostly a POD model,” owner Nancy Quatrano of On-Target Words also bemoans problems on the production end of the supply chain. “Several orders with Ingram have resulted in returns of up to 10% of the books ordered for printing issues,” she says. These problems included crooked pages, pages glued shut, and incorrect interior files. In the end, Ingram replaced the problematic books, but Quatrano says the process of documenting the errors and waiting for a determination was time-consuming.

Delays in production and delivery have also forced On-Target Words to adjust launch and event schedules. “Once upon a time, the only time we experienced lead times greater than 18 days was during the Christmas printing season,” she says. “Now we seem to be unable to get books in less than 28 days with any certainty.”

The Flexibility Advantage

With characteristic adaptability, independent publishers are adjusting their practices to address challenges on the production end of the supply chain. At Stone Bridge, Goodman says, “Printer schedules, paper supply, and increased costs have made us rethink formats, workflow, advances, royalty rates, and whether or not to keep titles in print.”

With these recalibrations, Stone Bridge is expanding its range of on-demand printers and getting projects to them with ample lead time. Goodman is also increasing print runs on some titles to avoid reprint scheduling issues. On other titles, he is cutting runs to reduce warehouse overstock. He is also shifting to POD for some projects, with concurrent retail price increases to offset the higher printing costs.

With production costs rising, Biel worked with his printers to see where savings could be found. In one instance, he discovered that the printer had changed its standard trim sizes, which left Microcosm paying for custom trimming. By adjusting his trims, he says he saved a few thousand dollars per book.

Biel recommends publishers shop for printers who’ll be the best fit for their projects. For some, that means tapping into a trend toward reshoring production. “The biggest shift I’ve seen in the past four years is publishers getting in touch to ask me how to print in the US,” he says. “It's not as difficult or expensive as publishers believe.”

At On-Target Words, Quatrano has taken this advice to heart, moving entirely to domestic production. As a safeguard against potential shortfalls, the company also warehouses small inventories and asks their authors to do the same. “The increase in pricing and production times and decline in quality mean we can’t count on the suppliers (as) we once did,” she says.

Citing declining paper quality, variable spine alignment, and the misalignment of hardcover flaps, CEO Bryna Haynes of WorldChangers Media has switched projects from POD to short-run printing. “I have been beyond impressed with both overall print quality and also pricing on smaller print runs,” she says. Haynes appreciates the responsiveness of her Virginia-based printer, which offers both short-run and POD options and is affiliated with a Pennsylvania distributor. “It makes all the difference in the world when you have a real relationship with the people you trust to produce, print, and distribute your books,” she says. “With the technology available, there are more great options for local-ish POD or small-run printing than you might believe.”

Where to find those alternatives? Motivated in part by missing “some prime retail opportunities” due to printing shortfalls, Riegert has launched Perfect Bound (perfectbound.io), a free two-sided marketplace for

independent publishers and printers. Likening the service to Airbnb, he uses the platform to source all his own print runs. “It has allowed us to manage our inventory much more conservatively and reprint faster both internationally and domestically,” he says.

On the Distribution End

At the other end of the supply chain, publishers are also working to counter post-pandemic distribution problems. As with production, costs have gone up, spurred in part by rising wages for the workers who get goods to market.

“If there is one thing that the pandemic changed for the next 10 years, it’s that workers want higher wages for thankless jobs or they simply won’t take them,” Biel says. “Publishers are going to have to see the validity of the people who put books into boxes as the most vital part of our industry. We can’t pretend they don’t exist anymore.”

For Haynes, distribution problems have been less about getting products to market and more about reporting, account management, and communication hassles with Amazon and Ingram. Additionally, several of her author services clients have found their Amazon KDP accounts inexplicably shut down, effectively ending Amazon’s distribution of those titles. “No one would explain why the accounts were shut down or what policies, if any, had been violated,” she says. “Those sales were not recoverable.”

Other links in the distribution chain have broken completely. In April of this year, the closure of Small Press Distribution (SPD) sent shock waves through the industry. Small literary presses that had relied on the nonprofit book distributor to get their books to customers learned overnight that their inventory had been temporarily shifted to either Ingram or Publishers Storage and Shipping.

The sudden closure left publishers scrambling to cover the costs of moving their inventory out of the temporary warehousing. Many also face the setup costs associated with new distribution arrangements. Noting shortfalls in payment from SPD, some publishers have set up GoFundMe campaigns to stay afloat.

Biel sees the SPD closure as a wakeup call for the industry. “After the collapse of SPD, I think it’s high time that some publishers looked into forming distribution cooperatives that they own,” he says. Featured in a recent IBPA webinar on distribution, Biel speaks from a place of success. “We fired our distributor and resumed handling our own distribution in 2018,” he says. “Our sales doubled in the first year and quintupled over four years. This was a lifesaver over the past six years as we watched other publishers who were distributor-dependent suffer reduced sales.”

Informed Creativity

Though publishers may wish it otherwise, the supply chain demands their attention. On the production end, they face rising costs, inferior quality, and slow turnaround times. Snafus on the distribution end are wreaking havoc in the industry, too.

Ignoring the supply chain won’t make those problems go away. Biel urges publishers to stay informed and study their data. “Publishers who do not create P&Ls are going to risk severely negative impacts,” he says. “Know your numbers.”

In tandem with this advice, Riegert encourages independent publishers to tap into their trademark creativity. “Don’t take anything off the table,” he says. “Be creative with how you get your books to market. Backstop with POD platforms. Meet new printing partners and experiment with new formats.”

Weak and broken links in the supply chain may seem beyond a publisher’s control. But despite the challenges, nimble and informed independent publishers will find ways to prosper.

Deb Vanasse is the author of dozens of published books. She works as a freelance editor and is an author-publisher at Vanessa Lind Books.